Condition Monitoring on a Storm Surge Barrier

Maeslantkering

The Maeslantkering is one of the main storm surge barriers in the Netherlands and a structural marvel. The barrier is a crucial element in the protection of Rotterdam from flooding.

In 2007 the hydraulic drive system of the barrier wall was scheduled for the first large maintenance. Even though the hydraulic pumps had limited running hours the condition was worse than expected. In order to gain more insight in the behaviour of the systems and to have better control of maintenance cycles, HVR Engineering advised Rijkswaterstaat to install a monitoring system in 2007, which is still operational.

Monitoring System

The HVR Measurement system monitors the hydraulic system, but also the stresses in several structural components, such as the push-pull bar that connects the drive train to the main structure.

All the components are continuously monitored via the system and data is collected and saved on the measurement systems at site. Large sets of data will cover the time when the barrier wall is sitting on the foundation. These periods are important to understand the performance and behavior of the system when idle.

Several times a month during the winter season, which is typically the storm season in The Netherlands, the barrier walls are also floated as a precaution in case water levels will rise to critical levels. These periods provide valuable insights in the behavior of the system when controlling a floating wall.

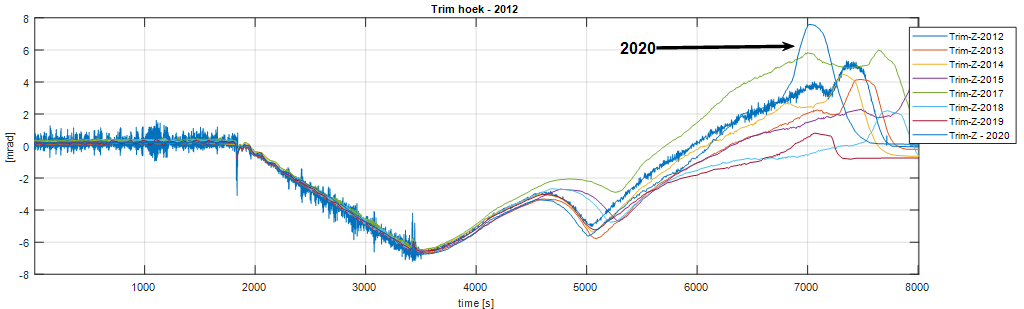

Besides the operational data, the most comprehensive data is collected during the annual high-floating and functional testing of the barrier walls. The data gathered during both tests are extensively analysed by HVR Engineering and trends are reviewed against previous years.

Data and Behavioral Analysis

Gathering extensive data via condition monitoring system is valuable, but only when this data is analysed accurately.

HVR Engineering collects data every three months, and after the annual tests. Based on our experience with measurement campaigns, hydraulic drive systems, and structural analysis, we have developed algorithms to visualize and review underlying behavior and performance of individual components.

The outcome of the analysis are reported to Rijkswaterstaat and specific advice is given to repair, or to further analyse components that are underperforming or showing irregular performance. Since the installation of the measurement system, the full 10-yearly overhaul cycle has been postponed and significant cost have been saved because of that.

FEM and Simulation of Maeslantkering

The Maeslantkering was built in the mid 1990s and completed in 1997. During the building phase of the barrier, and in the years after, HVR Engineering has supported Rijkswaterstaat on the Maeslantkering. This cooperation is now extended for another couple of years.

The coming years HVR Engineering will continue to support Rijkswaterstaat with condition monitoring on the Maeslantkering. In addition HVR Engineering will work on the development of a simulation model that can be used to simulate the behavior of the barrier wall when flooded and lowered onto the river bed. In order to accurately simulate this behavior, a complete 3D FEM model will first be developed to simulate trim angles and bending in the wall during floating and flooding phases.