Creation of a Simulation Model for the Maeslantkering

The Challenge

The Maeslantkering has been operational since 1997 and is tested every year to guarantee that the water barrier is ready for the upcoming storm season.

During the many tests it became evident that the system that controls the ballast, trim and position of barrier wall had to adjust more than what was anticipated in the design phase. To understand this behavior of the control system better, HVR Engineering was asked in 2017 to install a permanent condition monitoring system and analyse the data in detail every 3 months, during the high floating tests, and during the annual functional testing.

Analysis of the data has confirmed that the control system could be further optimized. To understand what changes would be needed, HVR Engineering is developing a simulator that can simulate and manipulate the behavior of the control system to find the optimum settings. To define the inputs of the simulation model accurately, first a full 3D FEM model is created.

Finite Element Model

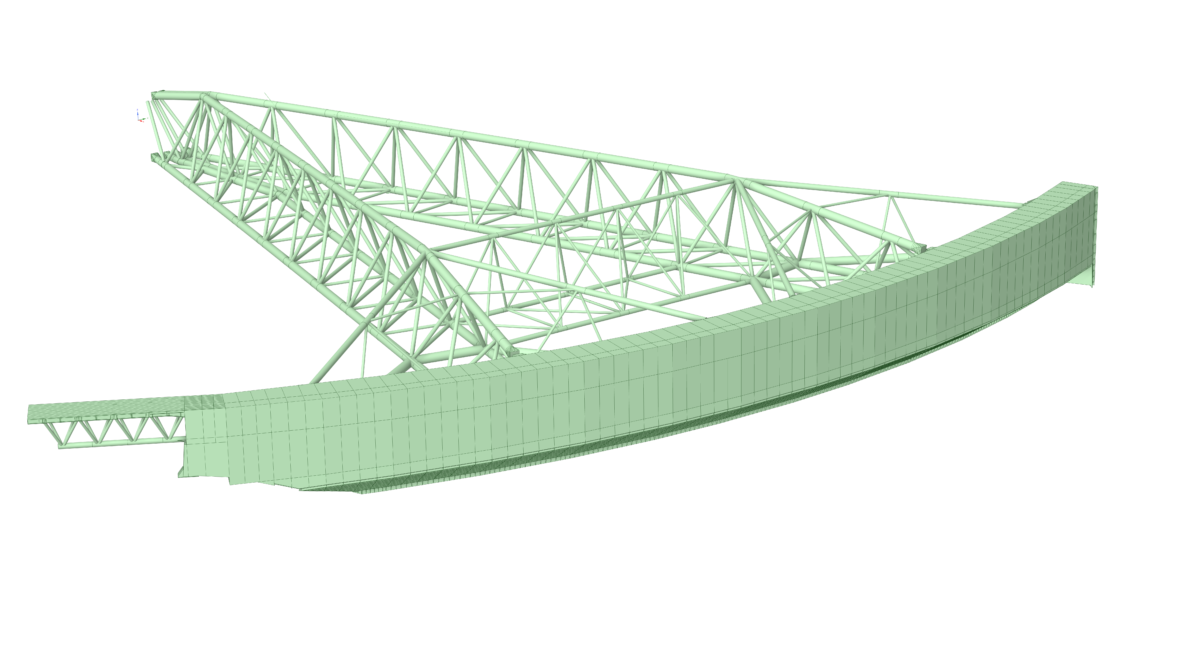

The Maeslantkering has two doors, each measures 220 meters in length, 22 meters in height and 15 meters in width. Understanding how these impressive structures are behaving when floating up the river before closing, when ballasting, or when being lowered onto the river bed, is essential to define the correct control parameters.

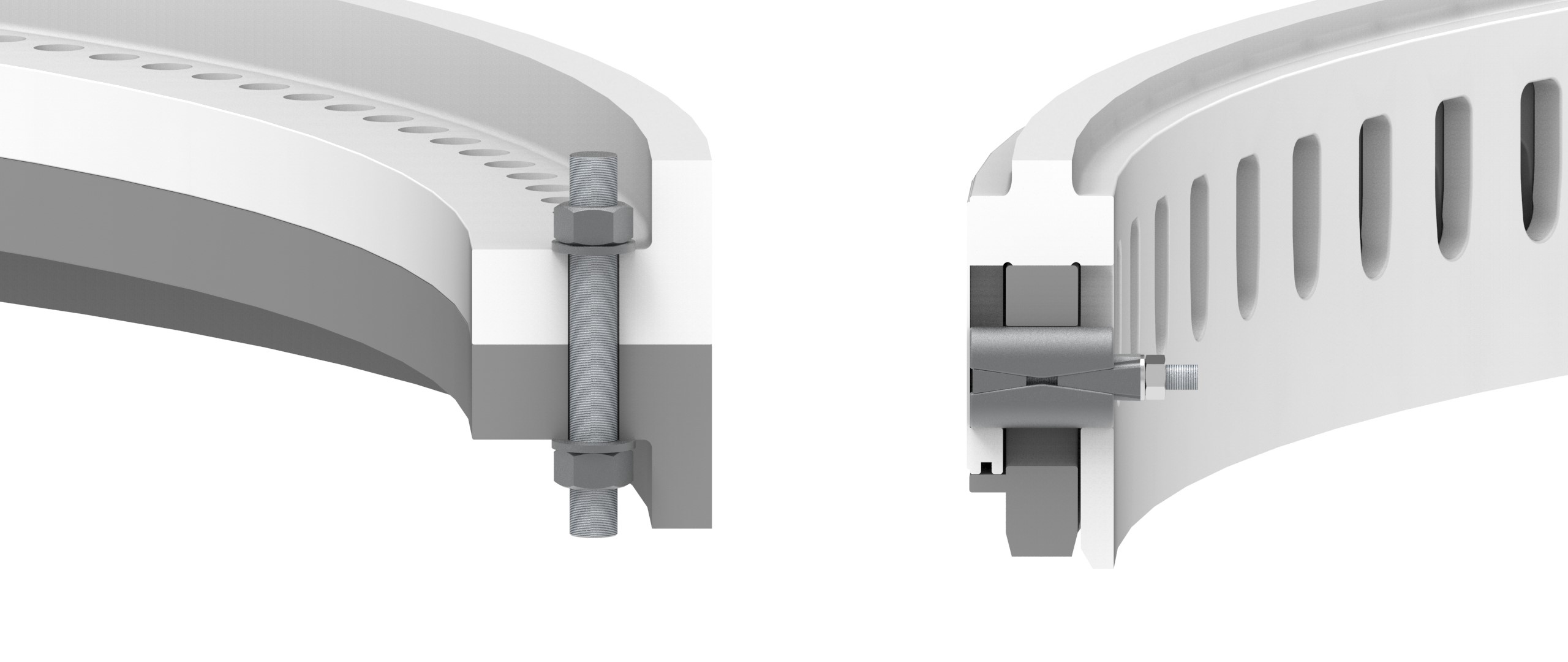

As part of this project, HVR Engineering therefore first develops a 3D FEM model to define the structural behavior of the barrier wall, the water displacement, and the ballast volume. The outputs of this phase will define how the barrier wall behaves in each phase during the closing and opening process and these values can be used in a simulation model to define the parameters of the control system.

Simulation Model

In the second phase of the project a detailed simulation model is created that accurately presents the dynamic and static behavior of the Maeslantkering. The model will be used to validate the current parameters of the barrier wall, by using the available data from more than 4 years of continuous monitoring. Based on the outcomes, the parameters for the control system will be further optimized to meet the design criteria.

Not only does the simulation model offer the possibilities to optimize the parameters of the control system. It also gives the asset manager of the barrier wall the opportunity to simulate different scenarios and validate various fault tree situations to also optimize the process should there be component failure.

Condition Monitoring

Detailed condition monitoring of the Maeslantkering has shown that there was room for further improvements of the both the drive system, but also the control system of the barrier wall. Read more about the Condition Monitoring System we installed on the Maeslantkering.

What we can do for you

Combining FEM, Measurements and Simulations gives the possibilities to accurately predict the behavior of any system. If you are interested how these services can help in your projects, then get in touch!