Dynamic FEA of the next generation Piling Hammer

The Challenge

The Offshore Wind market is undergoing an impressive development. The next generation Offshore Wind Turbine Generators (WTG) are pushing innovation in the entire supply chain.

The expectation is that the development of WTG will push the diameters of Monopiles – the most common type of foundation - to 10 meters. To drive these piles into the seabed a new hammer concept has been developed: the BLUE Piling hammer.

BLUE Piling

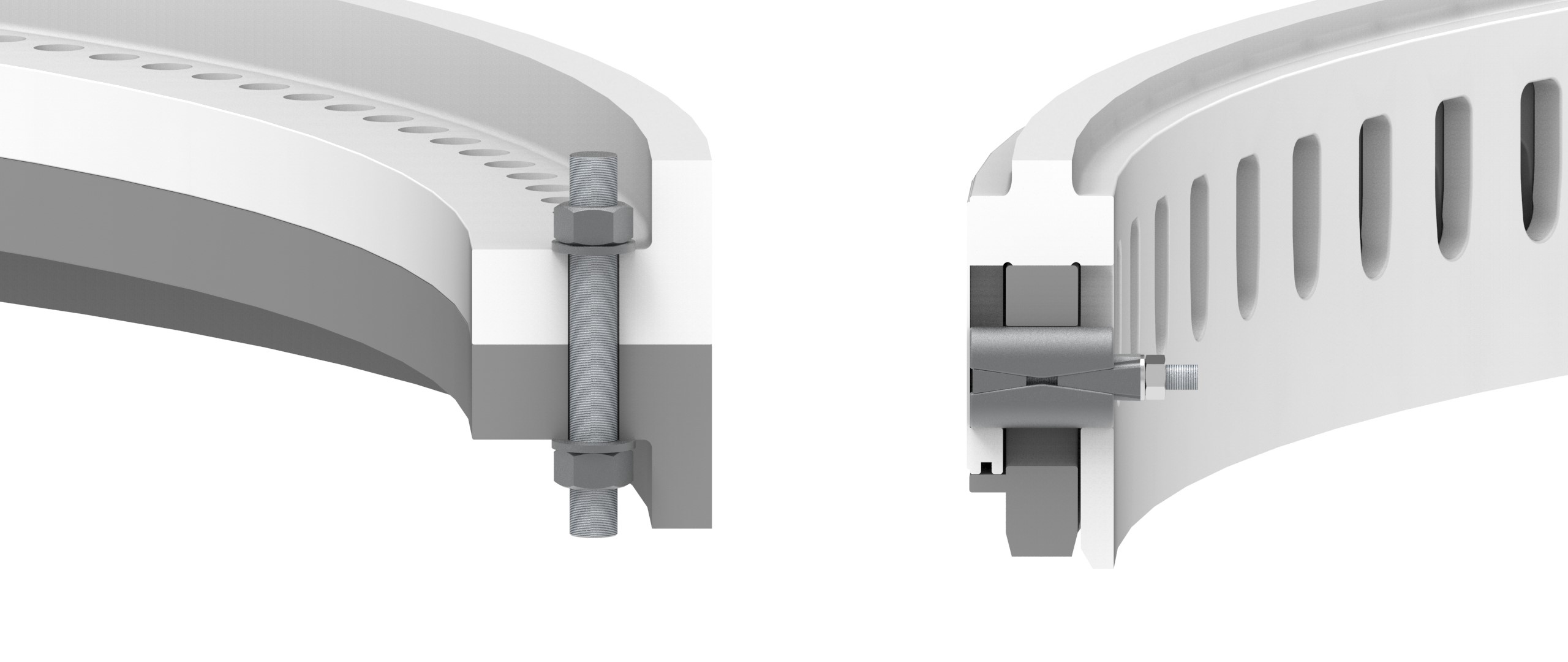

The BLUE Piling technology is an innovative piling solution that uses the deceleration of a large water mass to deliver a long-lasting blow to the pile. The technology reduces noise at the source during installation, ensuring a safe and environmental friendly installation.

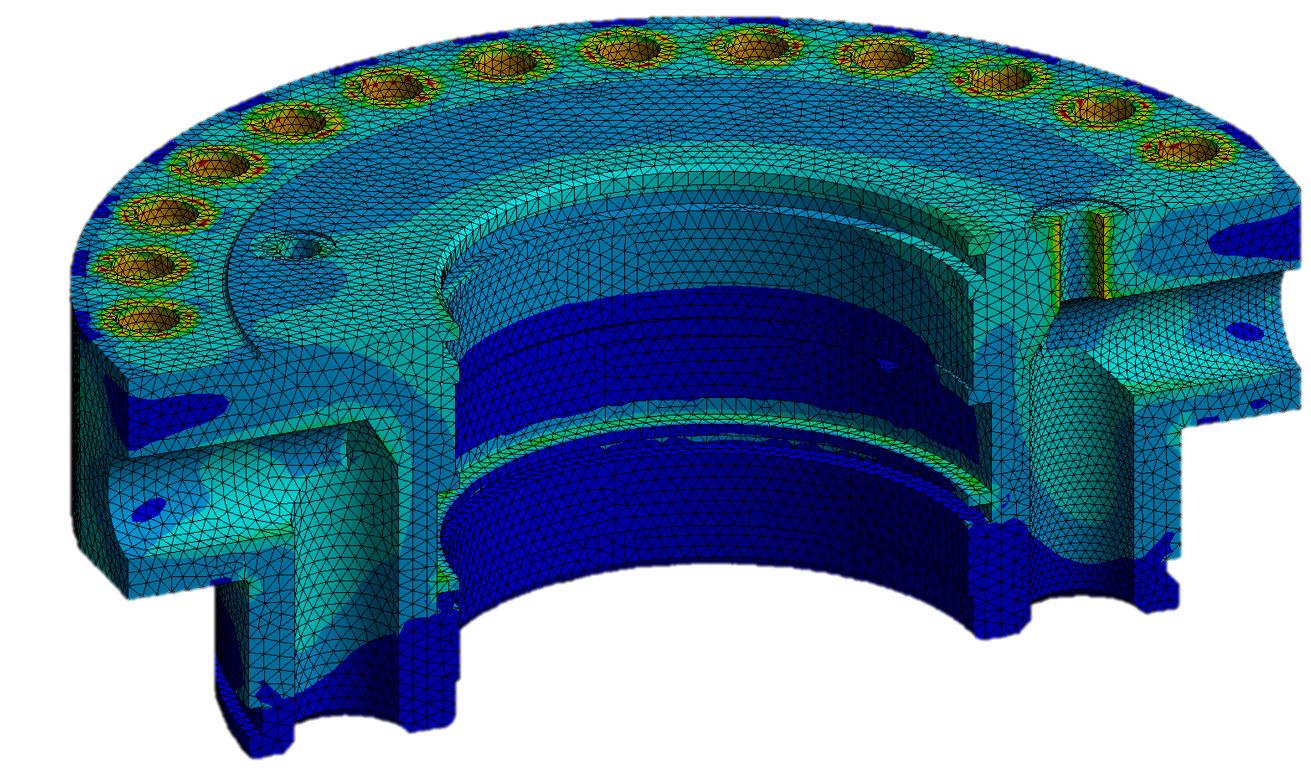

As with conventional hammers, the impact on the pile will generate high dynamic loads. To understand the effects of these loads on the hammer design, HVR Engineering performed many dynamic FEA and fatigue analysis to support with the development and optimization of the hammer.

Dynamic FEA

Similar to any new development, the BLUE Piling hammer consists of many new components, and since each of these components will either see a direct impact of the water mass, or indirect acceleration as a result of the impact, they were all verified via dynamic FEA.

HVR Engineering worked closely together with the team of BLUE Piling on the development of the hammer and some of the most innovative and critical components. All have undergone several optimizations via iterations that were a result of extensive Finite Element Analysis, where the effects of the water column have also been modelled to gain full understanding of the behavior of the hammer while driving.

Via Dynamic FEA and fatigue analysis HVR Engineering will actively contribute to optimizing the hammer further, so that when this reaches the market it will meet the harsh demands of driving the world’s largest and heaviest Monopile foundations offshore.

Importance of Verification

At HVR Engineering we have worked on various Piling Hammer developments over the years and developed dynamic impact simulation models to accurately model the behavior of these piling hammers and the effects on piles and pile design. An important element in this has always been verification of our models which we regularly do via the use of reference measurement data.

What we can do for you

Projects like these are pushing the envelope and are projects we enjoy working on. We can support with the development of innovative products and equipment via simulation models and FEM. Want to know more? Have a look at our other projects or get in touch!