Connecting the next generation offshore wind monopiles

The Challenge

C1 Connections has developed an innovative solution to connect a monopile foundation to the Transition Piece and Wind Turbine Tower. The unknown factor was how the connection would cope with pile driving.

Hammer and pile imperfections, combined with the highly dynamic behavior of pile driving, have a large effect on the stresses in the pile top. We have specialised in the detailed impact pile driveability analysis of this interaction and were approached by C1 Connections for this analysis.

Drivability Analysis

Pile driveability is an often underestimated aspect of any interface connection but essential for the design of a monopile.

Our Approach

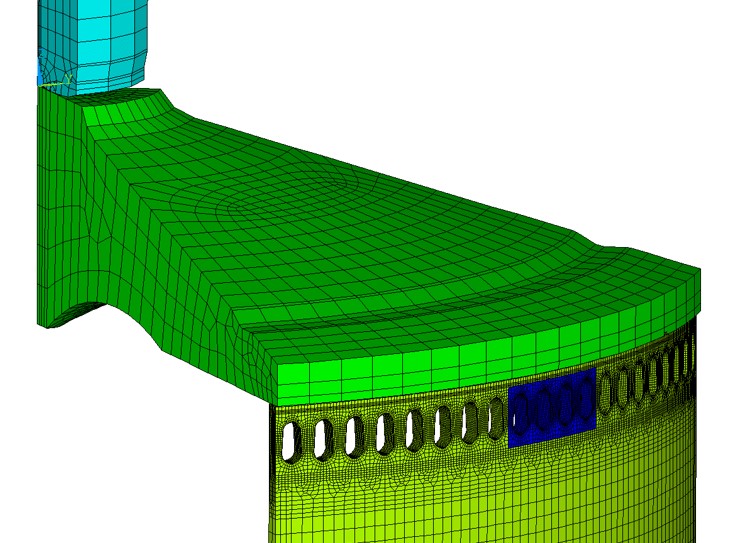

Due to the novelty of this connection, a thorough pile driveability analysis of the wedge connection was studied by means of nonlinear Finite Element Analysis.

Finite Element Analysis

An FEA model was developed to evaluate if a monopile with a wedge connection interface at the top can be driven with a large hydraulic impact hammer.

By executing refined 3D nonlinear dynamic analysis in ANSYS, we analysed the effects of the top pile geometry as a result of the forces rising in the connection during pile driving.

Design optimization

An in-depth analysis was executed to identify how local stresses were affected by the manufacturing tolerances of the components.

With the knowledge from the analysis, an optimized design of the pile top was proposed by HVR Engineering that reduces the stress occurring during installation at the most critical locations by 60%. This had a significant effect on improving the fatigue performances of the connection.

Valuable insights

“The design verification and optimization performed by HVR Engineering has given valuable insights in the optimization of the C1 Wedge Connection when the connection will be used on the top of a monopile,” says Mr. Winkes from C1.

“When we see that currently some wind farms are considering grouted connections again, it is more than clear that a connection with a higher capacity than an L-flange is sought after by the industry. With the analysis performed by HVR Engineering we feel confident that the C1 Wedge Connection can be installed with conventional impact hammers and that we have a solution for the work-horse of the industry: The Monopile.”

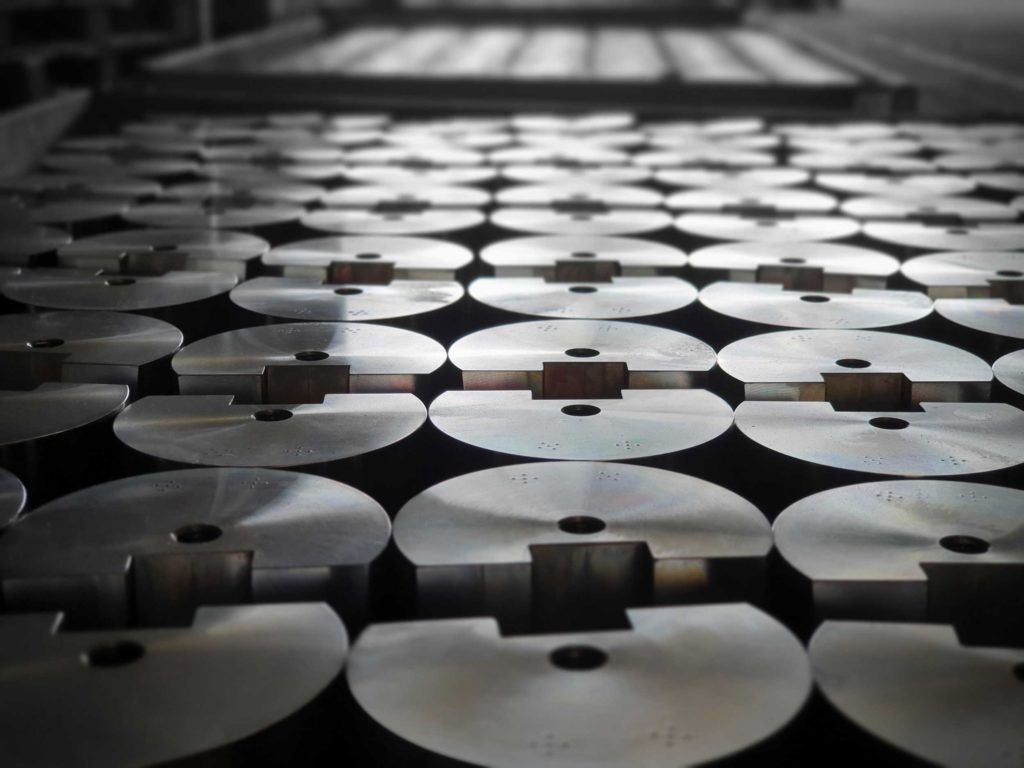

C1 Wedge Connection

The next generation Offshore Wind Turbines will have very high overturning moments, an issue that is already seen with turbines installed in Asian wind farms where Typhoons can have a massive impact on the load of the connection between foundation and tower.

As a results, next generation monopiles are designed with top diameters of seven to eight meters to accommodate equal sized turbine towers. Industry standard L-flange connections are facing limitations with these diameters in combination with high loads.

C1 Connections has developed the C1 Wedge Connection, an innovative solution to connect the monopile foundation to either the Transition Piece, or directly to the Wind Turbine Tower. “This solution creates a pre-stressed symmetric connection with special shaped holes in the top of the pile,” explains Mr. Winkes. “Fork shaped upper and lower members enclose special fasteners using wedges that create the symmetric pre-stress. Testing has demonstrated that the connection has an ultimate capacity that exceeds that of conventional bolted L-flange connections and that the connection is not fatigue sensitive. Further benefits lie in an enhanced safety of the connection and the fast installation process.”